NEWS CENTER

|

|

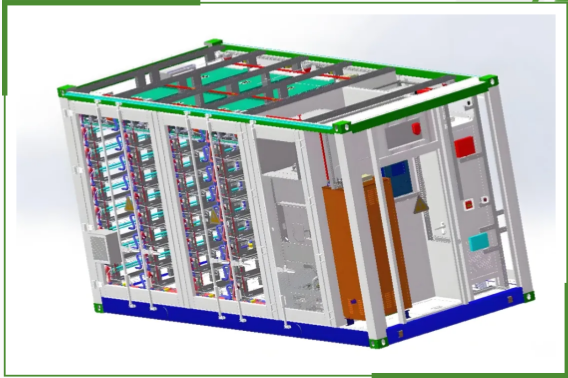

Key points of structural design of prefabricated energy storage cabinIn modern energy storage systems, cabin structure design is the core link to ensure safe operation. It must strictly follow national standards and design specifications, combine actual engineering needs, and optimize material selection and construction measures. This not only ensures that the structure meets the strength, stability and rigidity requirements during transportation, installation and use, but also effectively copes with waterproofing, fire prevention, corrosion prevention and harsh environmental challenges , provides reliable protection for equipment, and improves the overall durability and efficiency of the system.

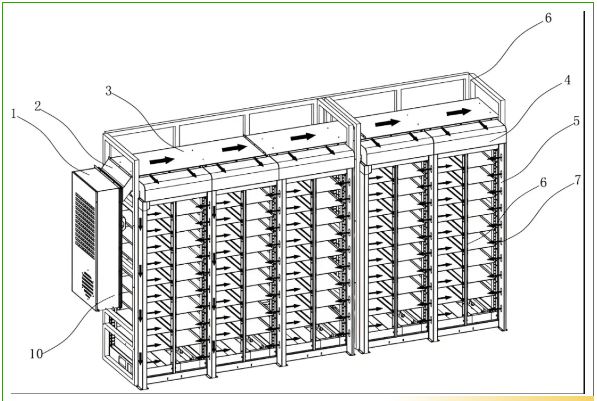

Overall design principles The overall structural design of the cabin must be based on current national standards and design specifications , and closely integrated with the actual project scenario. This includes the rational selection of materials, optimization of structural schemes and construction measures to ensure that the structure has sufficient strength, stability and rigidity during transportation and installation . At the same time, the design must fully cover key elements such as waterproofing, fire prevention, corrosion resistance and durability to adapt to extreme climatic conditions such as moisture, salt spray, severe cold and sandstorms. The container frame is centered on metal structural parts , requiring high rigidity and load-bearing capacity. It can withstand mechanical stress, thermal stress and electric force during installation, operation and short circuit of electrical components, and avoid damage or performance degradation due to lifting or transportation. The equipment casing must be flat, tight, beautiful and corrosion-resistant to ensure long-term and stable operation in harsh environments. The design process needs to focus on detail optimization. For example, the frame foundation should determine the load demand through calculation to ensure that the deflection deformation of the bottom plate steel beam meets the specifications. Anti-corrosion measures must be strictly implemented to prevent metal corrosion from affecting the overall life. In addition, the structure should be easy to maintain and upgrade to reduce later costs. The overall design also needs to consider economy and sustainability, select recyclable materials and optimize manufacturing processes. Through standardized sizes (such as ISO 20-foot or 40-foot containers) and safety specifications (such as UL 9540), ensure the convenience of the cabin in storage and transportation, while meeting fire isolation requirements and improving the overall reliability of the system.

Skeleton strength requirements of the cabin frame primarily focuses on the load-bearing capacity, which must be able to support the weight of the battery system, auxiliary equipment and other static loads. At the same time, the frame needs to cope with dynamic loads, such as vibration and impact during transportation and hoisting, which requires the overall structure to have high resistance to deformation . The frame should maintain good rigidity during operation to avoid damage to internal equipment or battery packs due to slight deformation. Especially when used outdoors, the ability to resist wind and snow is crucial, and the impact of wind pressure and snow load must be calculated to ensure structural stability. Integral welding is a recommended process that can enhance the strength and rigidity of the frame to prevent deformation or damage during lifting, transportation or installation. Design details include the precise calculation of the bottom plate steel dimensions, which must be based on load data to ensure that the deflection deformation meets the structural design specifications . This involves tools such as finite element analysis to simulate various stress scenarios. In addition, the frame should have a redundant design to cope with unexpected overloads. In harsh climates, such as high wind areas or snowy areas, the frame needs to improve its compressive resistance by strengthening the beam-column structure. The overall welding process requires strict quality control to avoid welding defects that affect strength. Through these measures, the frame can not only meet daily operational needs, but also remain stable in extreme events such as earthquakes, extending the service life of the cabin.

Material selection criteria Material selection is the core of cabin design. High-strength steel or aluminum alloy is often used for the frame to provide excellent strength, durability and corrosion resistance. These materials are not easily deformed under dynamic loads, ensuring structural integrity during long-term use. Surface treatment includes weather-resistant coating, anti-corrosion and anti-rust treatment, effectively resisting environmental erosion such as moisture and salt spray, and extending the life of the frame. At the same time, the material must comply with international size standards such as ISO container specifications for easy transportation and storage, and meet safety specifications such as UL 9540 and IEC 62933 to ensure fire and electrical safety. The choice of insulation materials is also critical. The surroundings of the box, the top plate and the bottom plate need to be filled with materials with low water absorption, low density and low thermal conductivity, such as rock wool or polyurethane foam, to provide good insulation and prevent cold bridges and dew points. The roof panel should be light, high-strength, corrosion-resistant and waterproof, and the middle layer should be made of non-flammable materials. The door material needs to have a high fire rating (such as UL 94 V-0) to ensure overall fire resistance. All materials must pass the GB 8624-2012 combustion performance classification test and take into account environmental protection, reduce the environmental impact during the production process, and improve the sustainability of the system.

Hatch and shell design The door design must meet the needs of equipment transportation and inspection , and adopt a fire door structure. The combustion performance and fire resistance limit of other building components should comply with GB 50016-2014 . The shell is made of cold-rolled steel plate or stainless steel plate, and is treated with anti-corrosion technology to ensure flatness, tightness and beauty. The shape of the box should not be easy to accumulate dust or water, reduce the use of exposed fasteners, and avoid screw penetration and water introduction. If fasteners must be used, stainless steel should be used to prevent rust. The connection between the cabin and the foundation must be firm, welded to the embedded parts, and sealed with weather-resistant silicone glue to prevent moisture intrusion. Ventilation and heat dissipation are the key points of the design. The hatch can be integrated with shutters or reserved for cooling equipment, and has waterproof and dustproof functions. Air pressure balance holes must be set to cope with the difference in air pressure inside and outside the box to ensure a stable internal environment. The door opening angle is not less than 90 degrees, and a limit fixing device is installed to ensure convenience and safety. The door body must be strong enough and will not affect the switch and sealing performance after hoisting and transportation. The size should match the equipment to facilitate the handling of large components. The overall shell design emphasizes the combination of beauty and function to enhance the user's operating experience.

Insulation and fire prevention measures The insulation design needs to ensure that the cabin has good thermal insulation performance. The filling material should have low water absorption, low density, low thermal conductivity and sufficient strength to prevent the formation of cold bridges and dew points. This requires the insulation layer to cover all sides of the box and optimize the thickness through calculation. Fire prevention measures include the use of high fire rating materials (such as UL 94 V-0) for the hatch and the middle layer, meeting the GB 8624-2012 standard. The overall structure needs to consider fire isolation, such as setting up fire partitions to deal with the risk of thermal runaway of the battery. The roof panel material needs to be lightweight and corrosion-resistant to provide double protection. Environmental control facilities such as heating, cooling and ventilation systems must be installed to ensure that electrical equipment operates within the allowable temperature range to avoid performance degradation or damage caused by high or low temperatures. The internal temperature must be stable to prevent dew points. The design needs to simulate extreme climate scenarios and optimize airflow paths. The shape of the shell avoids water and dust accumulation and reduces maintenance requirements. All sealing measures, such as silicone sealants, need to be checked regularly to ensure moisture-proof effects. Through these comprehensive measures, the cabin can adapt to various environments and improve system reliability.

Installation and maintenance points The installation process emphasizes structural stability. The cabin must be firmly connected to the foundation and welded to the embedded parts to ensure that it does not deform during lifting and transportation. The floor is designed to be anti-static, which is convenient for cable laying and maintenance and reduces safety hazards. The size and strength of the door must match the equipment handling requirements, and the limit device must be installed after opening to prevent accidental closing. The overall installation must follow the standard process, including the setting of air pressure balance holes and the debugging of the ventilation system to ensure the balance of the internal environment. Maintenance design focuses on ease of operation. The internal layout of the cabin should facilitate maintenance access and reduce downtime. Anti-static floors need to be cleaned regularly to prevent static electricity accumulation. Insulation materials need to be checked for integrity to prevent aging from affecting insulation. Shell fasteners and sealants should be inspected quarterly and damaged parts replaced in a timely manner. The environmental control system needs to monitor temperature and humidity to ensure that the equipment operates within the allowable range. Through these measures, the cabin can maintain high performance and reduce failure rates during long-term use.

|